Refrigeration and A/C

The worldwide trend for increased use of renewable energy leaves one of its sectors either underutilized or sometimes even neglected. This is a low temperature (below 100C) heat, abundant in industry and nature and relatively easy and inexpensive to recover from many sources – waste, solar, geothermal. The cost effective, reliable and environmentally friendly systems that convert low grade heat for cooling and possibly for ORC power generation may be thought as one of most important contemporary market demands.

„Will we be able to afford air-conditioning in the future?”- this was the question posed recently by one keynote speaker at a major worldwide technical conference. Indeed, with climate change and more restrictive regulations in power generation, the industry must look for other sources of energy besides electricity from fossil fuels.

Marani USA, Inc. is exploring the use of renewable, low-grade heat for powering cooling installations. The objective of the project is to develop the technology platform for innovative refrigeration and A/C powered by low temperature waste heat, which can be recovered from various industrial processes and especially from compressed air systems with use of environmentally friendly working fluids. Practical use of low-grade waste heat present many technical challenges due to low temperatures, in the range of 60-100C (158-212F).

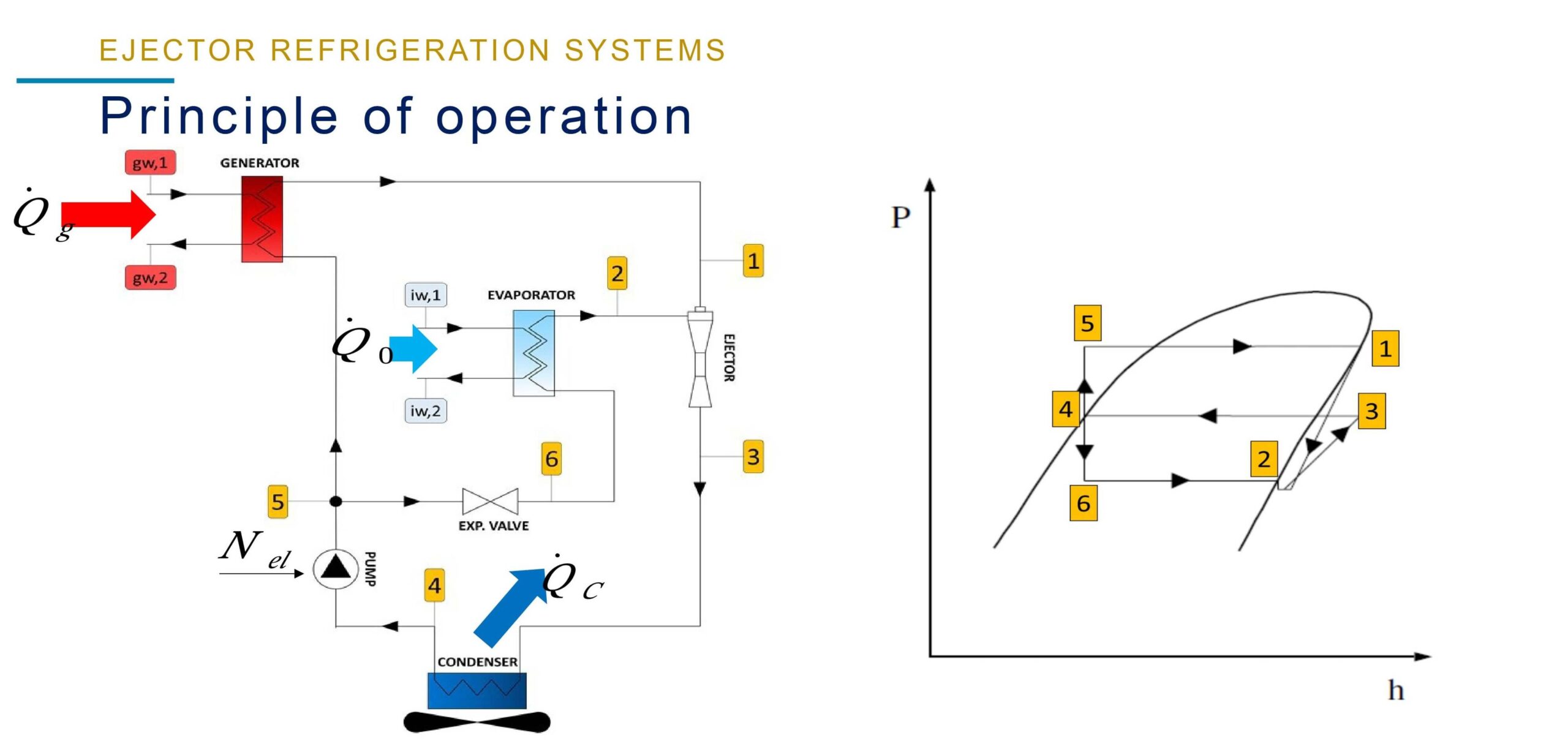

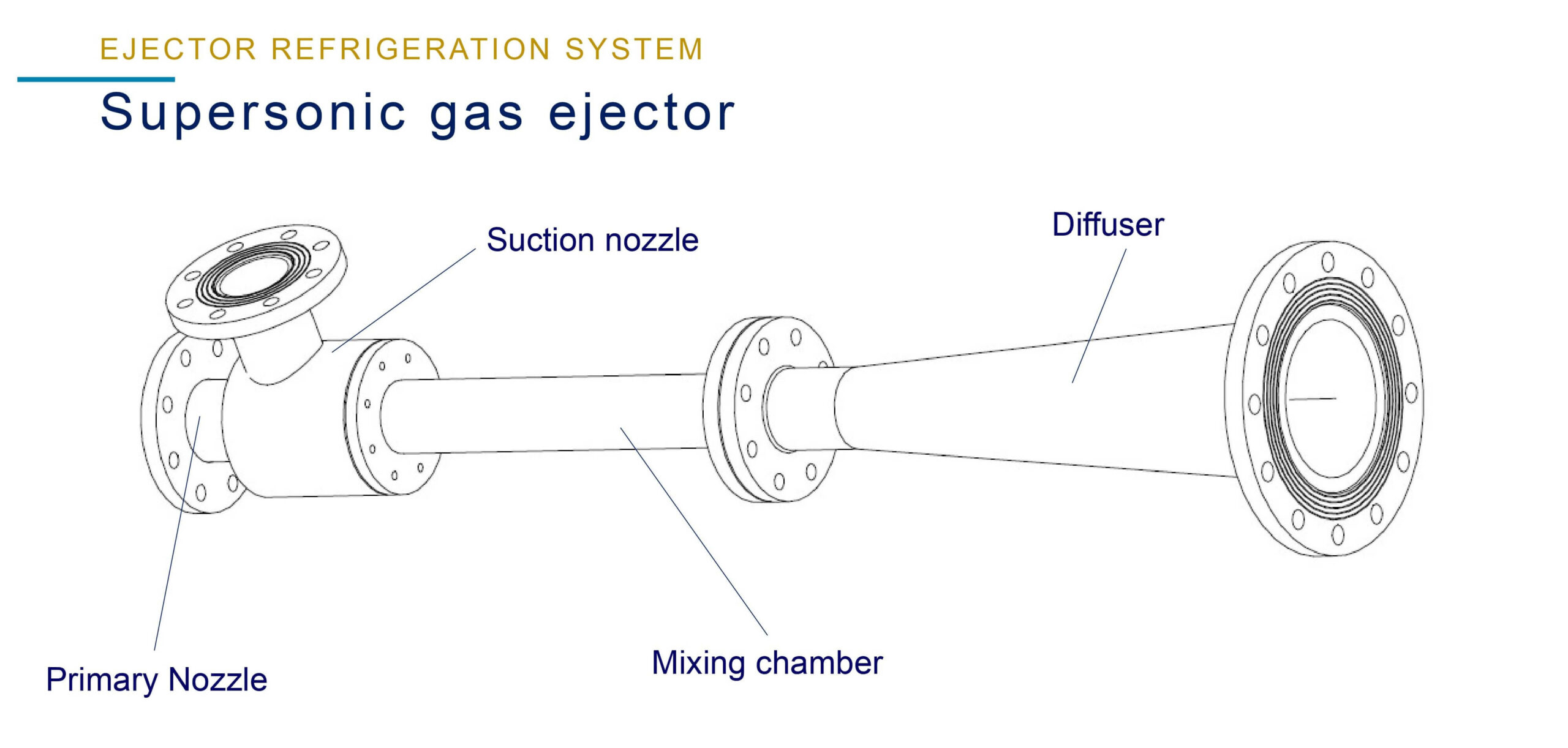

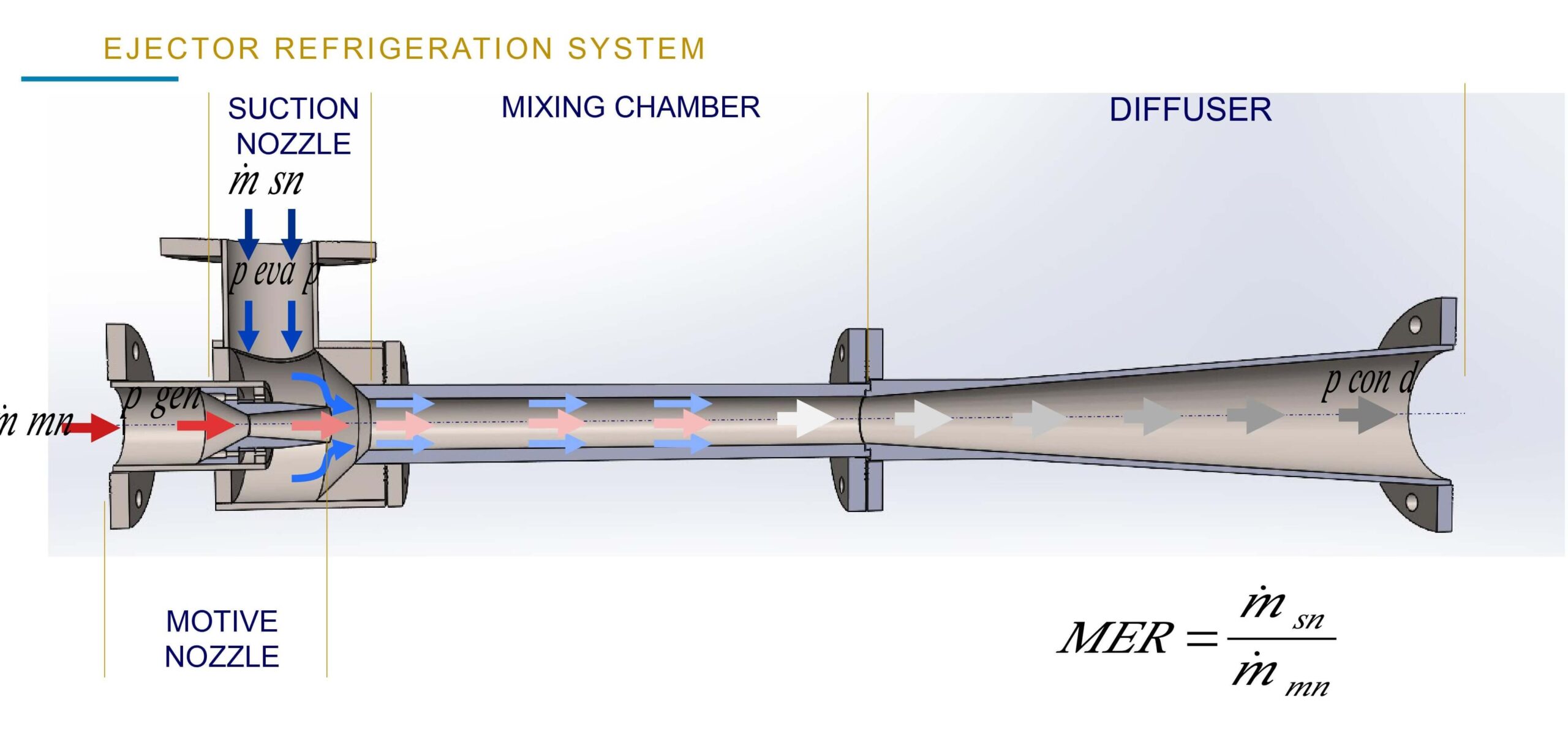

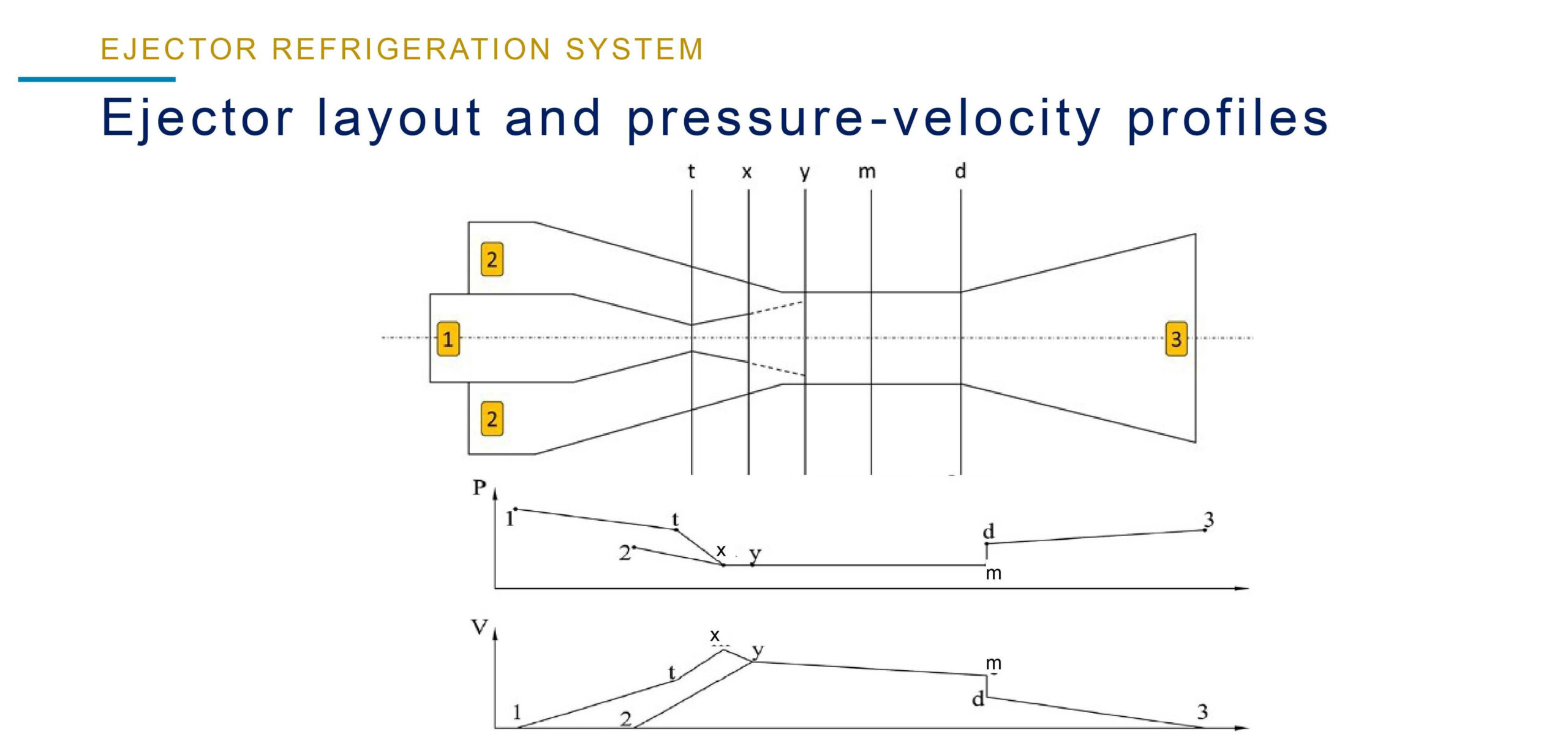

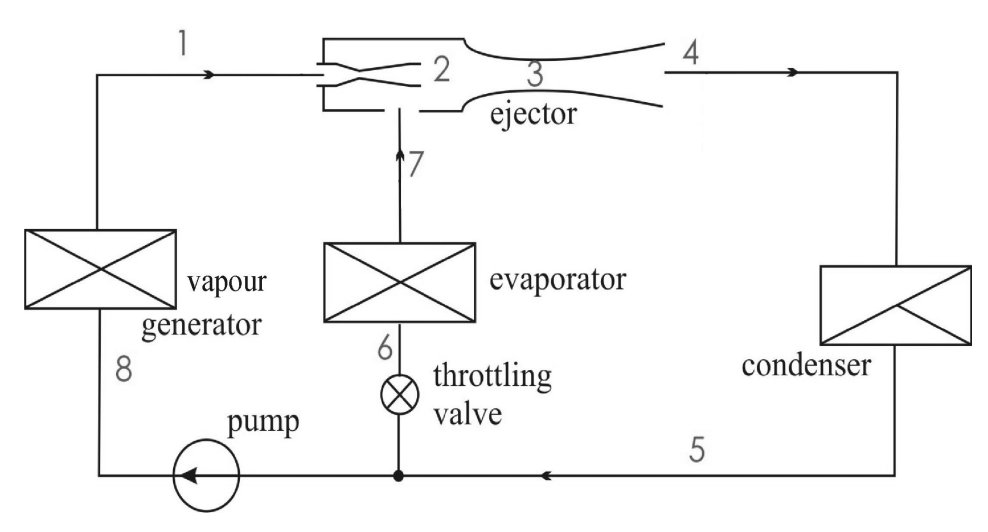

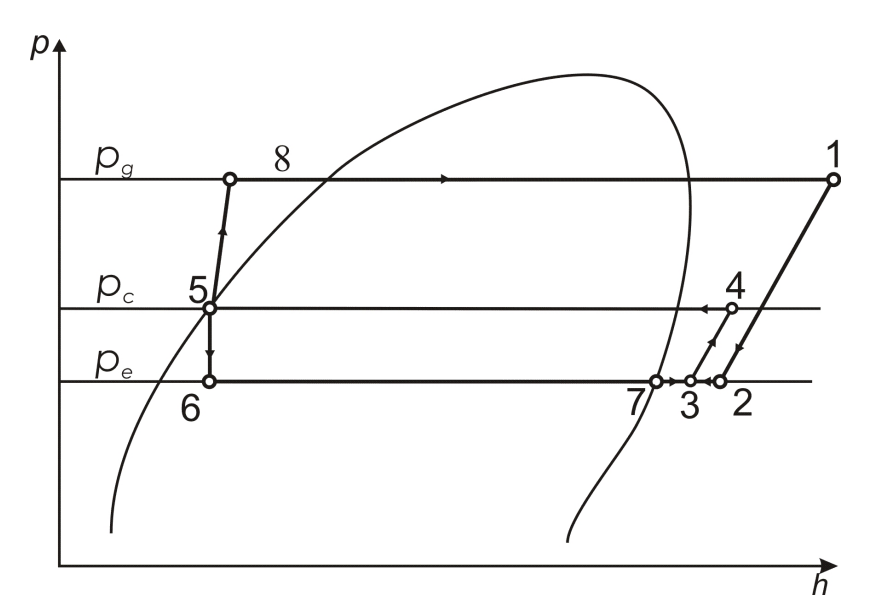

Our technology is based on ejector refrigeration system. Its conceptual schematics together with a thermodynamics cycle in p-h coordinates are pshown below in Fig. 1. Liquid refrigerant is passed through the pump to the generator (point 8). The liquid is then heated in the generator by either energy from solar panels or waste heat. First stage of heating produces saturated vapor, which is then heated further and leaves the generator in a superheated condition (point 1). Such superheated vapor enters the motive nozzle of the ejector and undergoes expansion from the generator pressure pg to the evaporation pressure pe (point 2). The ejector sucks vapor flowing from the evaporator (point 7), mixes it with expanded vapor (point 2) and, in consequence, the mixed vapor in state 3 is obtained. The pressure of the working fluid initially rises slightly as a result of momentum exchange, and then it rises more due to a shockwave up to the point 4, achieving the level of the condensation pressure pc. Compressed vapor enters the condenser, where it condenses and may also subcool depending on cooling conditions in the condenser. The working fluid leaves the condenser in the liquid state (point 5). It is then divided into two parts: one part flows to the generator through the small circulating pump. Meanwhile, the remaining part flows through the expansion valve to the evaporator where it is throttled to the evaporation pressure of pe, achieving the condition of wet vapor (point 6). Through boiling in the evaporator, the working fluid absorbs cooling capacity Qo from the refrigerant; this is the source of the cooling effect

Fig. 1. Schematic diagram of ejector device (left) and thermodynamic cycle in pressure-enthalpy co-ordinates (right).

Besides eliminating the compressor, the fundamental difference between this ejector refrigeration cycle and the conventional one (reverse Rankine cycle) is that it requires three heat sources at different temperatures rather than two. These are (referring to Figure 1) (i) at the generator level (8-1), which is the temperature of the solar source and is in the range 70-100C, (ii) at the condensing level (4-5), which is the ambient temperature of 25-35C and (iii) at the evaporator temperature (6-7) at approx. 5-10C.

The lack of appropriate methods for ejector design was a main reason that similar systems have not been developed in the past. Our engineers and scientists are developing such methodology and testing it in a variety of thermodynamic cycles for cooling, heating and heat pumps.

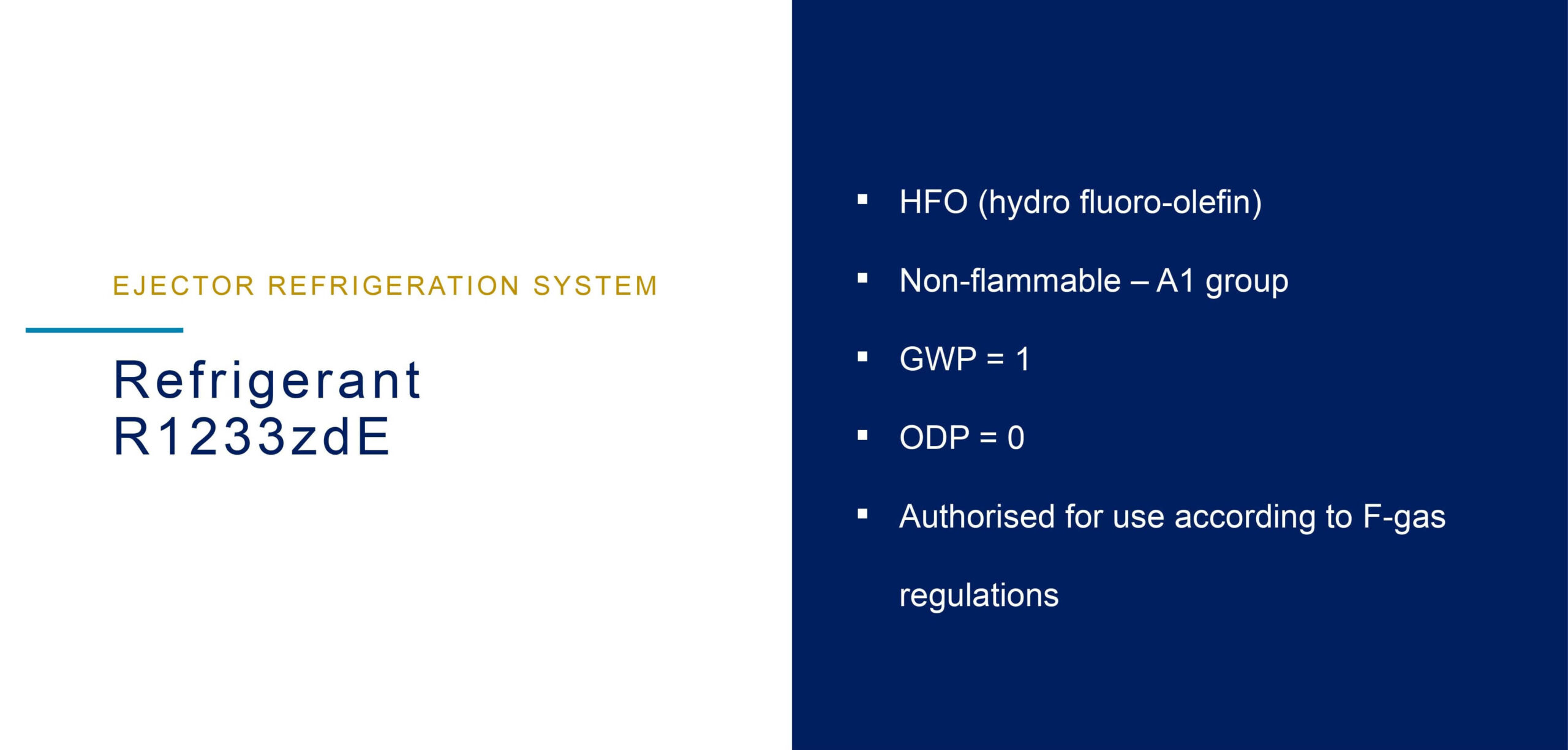

The key point is to use environmentally safe refrigerants that do not create neither Global Warming Potential (GWP) or Ozone Depletion Potential (ODP). We found that the maximum efficiency of the above system can be achieved with natural refrigerants (isobutene, propane, methanol, ammonia) However, primarily due to its flammable nature, some of them are not currently allowed in commercial systems in the USA and Canada. Therefore our research concentrates on newly developed synthetic refrigerants, such as R245fa, R1233 and R1234 (all of them having zero ozone depletion potential).

The innovation of the ejection refrigeration technique lies in the following:

1) utilizes a waste heat (or solar, geothermal) as the main source of energy,

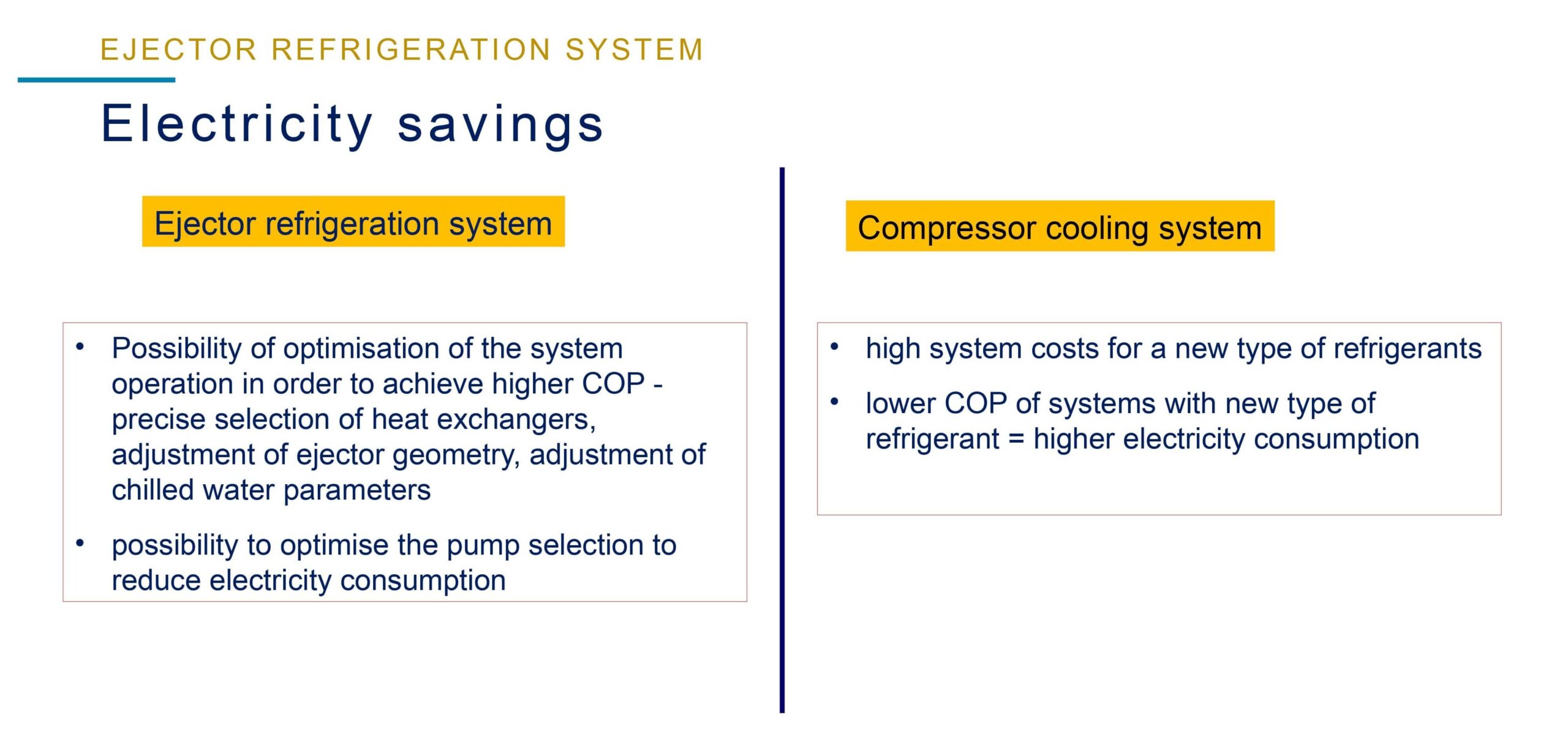

2) eliminates the mechanical compressor, which is the main user of electricity and the main contributor to maintenance and reliability issues, and

3) operates without any ozone depletion effects and greenhouse gas emissions, when used with natural refrigerants.

4) it offers a possibility to operate at lower driving temperatures as absorption methods

We are exploring many attractive applications in industry, buildings, agriculture and military. Examples are providing water at low temperatures for various industrial processes, powered by heat rejected from compressor station, residential and commercial A/C powered by solar heat, cooling computer/data centers with waste heat, cooling laptops with heat generated by microprocessor. Further, Dept. of Defense can use it for solar-powered cooling of field hospitals, clinics, command centers, mobile refrigerated storage for medicines, etc. A promising potential is a refrigeration in the Third World countries and in remote areas where electric energy is unavailable, also during disasters when even small amount of refrigeration could be life saving.